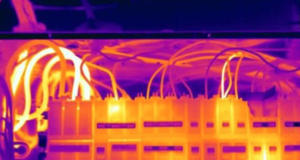

Electrical Thermal Imaging

Elevating Electrical Inspection: Unlocking Insights with Thermal Imaging

Innovative Solutions for Modern Challenges

Spotlight on Safety: Detect Issues Early

Don’t wait for disasters to strike. Our thermal imaging technology allows for early detection of electrical hotspots, ensuring the safety and reliability of your operations.

Future-Proof Your Facility: Stay Ahead of the Curve

Stay ahead of maintenance issues and regulatory requirements with proactive thermal imaging inspections. Safeguard your assets and maintain compliance effortlessly.

Unlocking Efficiency: The Commercial Benefits of Electrical Thermal Imaging

The practice of utilising thermal imaging for non-contact mechanical and electrical inspections is known as thermography. It involves the use of infrared (IR) or thermal cameras to capture and record temperature variations in mechanical and electrical equipment.

Thermal imaging and the application of thermal imaging in electrical inspections can be used in detecting issues during a non-intrusive inspection of your distribution equipment. If you’re in need of industrial thermal imaging services, rest assured, as we are commercial electricians serving the London and South East area.

What are the Advantages of Using Thermal Imaging for Electrical Inspections?

Understanding How a Thermal Camera Operates:

Thermal cameras detect and translate heat into a visual image.

These cameras consist of a lens, thermal sensor, processing electronics, and housing.

The lens concentrates infrared energy onto a thermal sensor.

Due to the larger wavelengths of thermal energy compared to visible light, thermal cameras typically have lower resolution and fewer pixels.

Sensors identify various temperatures and represent them with different colours, typically showcasing hotter areas in brighter colours and cooler areas in darker hues.

The use of thermal imaging for electrical inspections has become increasingly prevalent because malfunctioning electrical components often exhibit abnormal heat signatures. Consequently, thermal cameras aid in identifying problematic areas with ease. For instance, an electrical component or connection on the verge of failure will generate excess heat, which is detectable through thermal imaging.

Cost-effectiveness of Thermal Imaging:

Thermal imaging proves cost-effective as it requires only the hiring of a trained professional equipped with a thermal camera. Following inspection, captured images can be uploaded to a computer or smart device for analysis and reporting. Our team of professional commercial electricians not only provides detailed reports but also offers relevant advice and executes necessary repairs.

What Can Thermal Imaging Detect?

Thermal imaging is versatile, capable of scanning electrical cabinets, breaker panels, fuses, bolted connections, and switchgear. It can operate effectively in dark, foggy, or smoky conditions and is invaluable for various electrical procedures:

– Installation of electrical wiring and equipment

– Swift identification of hotspots or cold spots in large areas

– Troubleshooting errors in electrical connections

– Verifying the adequacy of equipment installation

– Ensuring compliance with electrical codes and safety standards

– Detecting broken or undersized wires and defective insulation

The rise in temperature within an electrical circuit can stem from diverse factors, including loose connections. Therefore, analysing heat patterns in electrical components aids in pinpointing faults and assessing their severity.

Additionally, the efficacy of thermal imaging hinges on the emissivity level of the electrical component. Objects with higher emissivity levels emit thermal energy more efficiently, resulting in more accurate thermal images.

Electrical Components Compatible with Thermal Imaging:

– Damaged Fuses. Thermal imaging facilitates the identification of overheating in damaged fuses, while blown fuses appear as cold spots.

– Electrical Imbalance: By assessing heat signatures, thermal imaging can pinpoint imbalances in panels and connection points.

– Connections and Wiring: Thermal imaging highlights connections with elevated temperatures, often indicative of loose or corroded connections.

– Motor Control centre’s: Thermal imaging reveals heavily loaded motor control centre’s, aiding in maintenance assessments.

– Transformers: Thermal imaging helps examine various components of transformers, including external connections and cooling mechanisms.

For businesses in need of thermal imaging services from a commercial electrician in the Commercial area, Industrial Power & Automation we offer comprehensive solutions.

Our range of thermal imagers ensures thorough inspections and timely detection of potential malfunctions, enhancing efficiency, accuracy, and safety in electrical systems

Non-intrusive Proactive maintenance

For commercial clients who need to limit shut downs of the installation, but still require a planned and reactive maintenance strategy to ensure the safety of their electrical installation.

Designed to reduce potential down time of your business due to failure components failure

Periodic inspections are part of an overall maintenance strategy, whether annually or quarterly we are here to meet your needs

Experienced in health and safety

We will complete a method statement (RAMS) before undertaking any thermal imaging assessments. Any safety concerns raised will be identified and considered.